Cyclic Loading

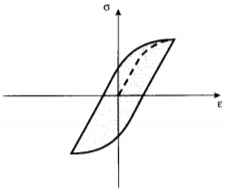

Specimens loaded cyclically so as to alternate between tension and compression can exhibit hysteresis loops if the loads are high enough to induce plastic flow (stresses above the yield stress). [1] The enclosed area in the loop seen below is the strain energy per unit volume released as heat in each loading cycle. This is the well-known tendency of a wire that is being bent back and forth to become quite hot at the region of plastic bending. The temperature of the specimen will rise according to the magnitude of this internal heat generation and the rate at which the heat can be removed by conduction within the material and convection from the specimen surface.

Specimen failure by cracking is inhibited in compression, since cracks will be closed up rather than opened by the stress state. A number of important materials are much stronger in compression than in tension for this reason. Concrete, for example, has good compressive strength and so finds extensive use in construction in which the dominant stresses are compressive. But it has essentially no strength in tension, as cracks in sidewalks and building foundations attest: tensile stresses appear as these structures settle, and cracks begin at very low tensile strain in unreinforced concrete.

References

- ↑ Roylance, D. (2001, August 23). STRESS-STRAIN CURVES.