Differential Scanning Calorimetry: Difference between revisions

No edit summary |

|||

| Line 8: | Line 8: | ||

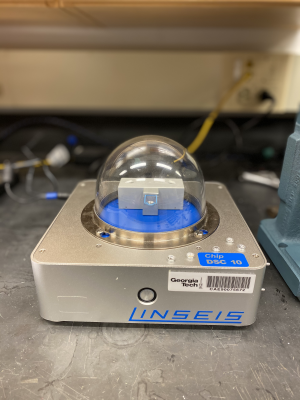

The Linseis Differential Scanning Calorimeter (DSC) is a thermal testing instrument used for measurements of material properties such as transformation temperatures, enthalpies of transformation, and heat capacities. It is capable of measuring temperatures up to 500 degrees Celsius and can use both solid and liquid specimens. | The Linseis Differential Scanning Calorimeter (DSC) is a thermal testing instrument used for measurements of material properties such as transformation temperatures, enthalpies of transformation, and heat capacities. It is capable of measuring temperatures up to 500 degrees Celsius and can use both solid and liquid specimens. | ||

== Thermal Properties of Polymers == | |||

=== Heat Capacity === | |||

The heat capacity (Cp) of a system is the amount of heat needed to raise its temperature 1 ◦C. It is usually given in units of Joules/ ◦C and can be found from the heat flow and heating rate. The heat flow is the amount of heat supplied per unit time Heat flow = heat time = q t (1) where t is time. The heating rate is the time rate change of temperature Heating rate = ∆T t (2) where ∆T is the change in temperature. One can obtain the heat capacity from these quantities Cp = q t ∆T t = q ∆T (3) This means the heat capacity can be found by dividing the heat flow by the heating rate. If the Cp of a material is constant over some temperature range, then the plot of heat flow against temperature will be a line with zero slope as shown in Figure 1. If the heating rate is constant then the distance between the line and the x axis is proportional to the heat capacity. If heat is plotted against temperature then the heat capacity is found from the slope. | |||

=== Glass Transition === | |||

If a polymer in its molten state is cooled it will at some point reach its glass transition temperature (Tg). At this point the mechanical properties of the polymer change from those of an elastic material to those of a brittle one due to changes in chain mobility. A typical example of a heat flow versus temperature plot at a glass transition temperature is shown in Figure 2. The heat capacity of the polymer is different before and after the glass transition temperature. The heat capacity Cp of polymers is usually higher above Tg. DSC is a valuable method to determine Tg. It is important to note that the transition does not occur suddenly at one unique temperature but rather over a range of temperatures. The temperature in the middle of the inclined region is taken as the Tg. | |||

Figure 2: Schematics of a glass transition. The glass transition results in a kink in the heat versus temperature plot due to the change in heat capacity (A). In a plot of heat flow versus temperature it is a gradual transition that occurs over a range of temperatures (B). The glass transition temperature is taken to be the middle of the sloped region. | |||

=== Crystallization === | |||

Above the glass transition temperature the polymer chains have high mobility. At some temperature above Tg the chains have enough energy to form ordered arrangements and undergo crystallization. Crystallization is an exothermic process, so heat is released to the surroundings. Less heat is needed to keep the heating rate of the sample pan the same as that of the reference pan. This results in a decrease in the recorded heat flow. If the convention of ‘exothermic - down’ is used then the result is a dip in the plot of heat flow versus temperature as seen in Figure 3. Such a crystallization peak can be used to confirm that crystallization occurs in the sample, find the crystallization temperature (Tc) and determine the latent heat of crystallization. The crystallization temperature is defined as the lowest point of the dip. The latent heat (enthalpy) of crystallization is determined from the area under the curve. | |||

Figure 3: Example of a crystallization ‘peak’ in a plot of heat flow against temperature. Crystallization is an exothermic process, so the heat flow to the sample must be decreased to maintain a constant heating rate. | |||

=== Melting === | |||

The polymer chains are able to move around freely at the melting temperature (Tm) and thus do not have ordered arrangements. Melting is an endothermic process, requiring the absorption of heat. The temperature remains constant during melting despite continued heating. The energy added during this time is used to melt the crystalline regions and does not increase the average kinetic energy of the chains that are already in the melt. In a plot of heat against temperature this appears as a jump discontinuity at the melting point as seen in Figure 4A. The heat added to the system during the melting process is the latent heat of melting. It can be calculated from the area of a melting peak observed in a plot of heat flow against temperature, such as the one in Figure 4B. The Tm is defined as the temperature at the peak apex. After melting the temperature again increases with heating. However, the heat capacity of a polymer in the melt is higher than that of a solid crystalline polymer. This means the temperature increases at a slower rate than before. | |||

Figure 4: Melting is an endothermic process so the heat flow to the sample must be increased to keep the heating rate constant, resulting in a discontinuity in the plot of heat versus temperature (A). This appears as a peak if the heat flow is plotted against temperature (B). The area under the curve can be used to calculate the latent heat of melting. | |||

== Applications == | == Applications == | ||

Revision as of 16:52, 25 June 2021

| Linseis Chip DSC 10 |

|---|

| Maximum Temperature: 500[math]\displaystyle{ ^{\circ} }[/math]C |

The Linseis Differential Scanning Calorimeter (DSC) is a thermal testing instrument used for measurements of material properties such as transformation temperatures, enthalpies of transformation, and heat capacities. It is capable of measuring temperatures up to 500 degrees Celsius and can use both solid and liquid specimens.

Thermal Properties of Polymers

Heat Capacity

The heat capacity (Cp) of a system is the amount of heat needed to raise its temperature 1 ◦C. It is usually given in units of Joules/ ◦C and can be found from the heat flow and heating rate. The heat flow is the amount of heat supplied per unit time Heat flow = heat time = q t (1) where t is time. The heating rate is the time rate change of temperature Heating rate = ∆T t (2) where ∆T is the change in temperature. One can obtain the heat capacity from these quantities Cp = q t ∆T t = q ∆T (3) This means the heat capacity can be found by dividing the heat flow by the heating rate. If the Cp of a material is constant over some temperature range, then the plot of heat flow against temperature will be a line with zero slope as shown in Figure 1. If the heating rate is constant then the distance between the line and the x axis is proportional to the heat capacity. If heat is plotted against temperature then the heat capacity is found from the slope.

Glass Transition

If a polymer in its molten state is cooled it will at some point reach its glass transition temperature (Tg). At this point the mechanical properties of the polymer change from those of an elastic material to those of a brittle one due to changes in chain mobility. A typical example of a heat flow versus temperature plot at a glass transition temperature is shown in Figure 2. The heat capacity of the polymer is different before and after the glass transition temperature. The heat capacity Cp of polymers is usually higher above Tg. DSC is a valuable method to determine Tg. It is important to note that the transition does not occur suddenly at one unique temperature but rather over a range of temperatures. The temperature in the middle of the inclined region is taken as the Tg.

Figure 2: Schematics of a glass transition. The glass transition results in a kink in the heat versus temperature plot due to the change in heat capacity (A). In a plot of heat flow versus temperature it is a gradual transition that occurs over a range of temperatures (B). The glass transition temperature is taken to be the middle of the sloped region.

Crystallization

Above the glass transition temperature the polymer chains have high mobility. At some temperature above Tg the chains have enough energy to form ordered arrangements and undergo crystallization. Crystallization is an exothermic process, so heat is released to the surroundings. Less heat is needed to keep the heating rate of the sample pan the same as that of the reference pan. This results in a decrease in the recorded heat flow. If the convention of ‘exothermic - down’ is used then the result is a dip in the plot of heat flow versus temperature as seen in Figure 3. Such a crystallization peak can be used to confirm that crystallization occurs in the sample, find the crystallization temperature (Tc) and determine the latent heat of crystallization. The crystallization temperature is defined as the lowest point of the dip. The latent heat (enthalpy) of crystallization is determined from the area under the curve.

Figure 3: Example of a crystallization ‘peak’ in a plot of heat flow against temperature. Crystallization is an exothermic process, so the heat flow to the sample must be decreased to maintain a constant heating rate.

Melting

The polymer chains are able to move around freely at the melting temperature (Tm) and thus do not have ordered arrangements. Melting is an endothermic process, requiring the absorption of heat. The temperature remains constant during melting despite continued heating. The energy added during this time is used to melt the crystalline regions and does not increase the average kinetic energy of the chains that are already in the melt. In a plot of heat against temperature this appears as a jump discontinuity at the melting point as seen in Figure 4A. The heat added to the system during the melting process is the latent heat of melting. It can be calculated from the area of a melting peak observed in a plot of heat flow against temperature, such as the one in Figure 4B. The Tm is defined as the temperature at the peak apex. After melting the temperature again increases with heating. However, the heat capacity of a polymer in the melt is higher than that of a solid crystalline polymer. This means the temperature increases at a slower rate than before.

Figure 4: Melting is an endothermic process so the heat flow to the sample must be increased to keep the heating rate constant, resulting in a discontinuity in the plot of heat versus temperature (A). This appears as a peak if the heat flow is plotted against temperature (B). The area under the curve can be used to calculate the latent heat of melting.

Applications

The glass transition temperatures ([math]\displaystyle{ T_g }[/math]), melting points, cold crystallization temperature ([math]\displaystyle{ T_c }[/math]), and recrystallization temperature ([math]\displaystyle{ T_{rc} }[/math]) can be found from the peaks in the DSC plot or local maximum of the first derivative of heat flow vs. temperature (for [math]\displaystyle{ T_g }[/math]). The enthalpy values of cold crystallization ([math]\displaystyle{ \Delta H_c }[/math]), melting ([math]\displaystyle{ \Delta H_m }[/math]), and recrystallization ([math]\displaystyle{ \Delta H_{rc} }[/math]) transitions (where applicable) for each sample can be determined from trapezoidal Riemann sums which calculate the area under each peak. The heat capacity of each sample ([math]\displaystyle{ C_p }[/math]) at a certain temperature can be calculated by dividing the heat flow at that temperature by the heating rate. The percentage crystallinity ([math]\displaystyle{ X_C }[/math]) was calculated from the following equation:

[math]\displaystyle{ X_C = \frac{\Delta H_m}{\Delta H^\circ_m} \cdot 100\% }[/math]

where [math]\displaystyle{ \Delta H^\circ_m }[/math] is the melting enthalpy for a 100% crystalline sample (found in literature).

Test Parameters

DSC has several test parameters that are crucial to set to proper values based on the sample(s) being tested in order to obtain the best data possible. These include the endpoints, ramp rate, and number of heating/cooling cycles. The endpoints when testing an unknown polymer should be determined by the maximum temperature that the DSC model is capable of and the degradation temperature of that polymer (can be found from TGA). Changing the ramp rate of the DSC can affect the sensitivity and resolution of the measurements and the appearance of the curves. A high ramp rate (such as 50°C/min) increases sensitivity at the cost of resolution, while a very low ramp rate (0.1°C/min) could cause the sample to undergo unwanted annealing/crystallization. Multiple heating/cooling curves are used when a polymer has undergone processing to find its intrinsic values, while the first heating curve shows any processing the polymer has undergone.

In a situation where the initial heating curve of a semi-crystalline polymer such as PET shows a certain [math]\displaystyle{ T_g }[/math], [math]\displaystyle{ T_c }[/math], and [math]\displaystyle{ T_m, }[/math] the cooling rate can have a significant effect on the values of these parameters found in the following heating cycle. For a slow cool (~1°C/min) these values would be expected to decrease, while they would be expected to increase due to a very fast cool (~1000°C/min). The enthalpy of cold crystallization would be expected to decrease while enthalpy of melting would be expected to increase in the former scenario and while the opposite would be expected in the latter scenario.

Cold Crystallization vs. Recrystallization

While similar sounding, cold crystallization and recrystallization are different processes and are easily discernible in DSC analysis. Cold crystallization is an exothermic process that occurs during heating and consists of previously amorphous regions rearranging themselves into new crystallites from the thermal energy being put into the polymer during heating. An example of when cold crystallization occurs is when a semi-crystalline polymer has been rapidly quenched during processing, so it has been frozen in an amorphous state. Re-crystallization is also exothermic, but occurs during cooling and arranges molten polymer chains into ordered crystalline structures.