Moisture Analyzer: Difference between revisions

No edit summary |

No edit summary |

||

| Line 25: | Line 25: | ||

Sensitivity to heat • Presence of volatile constituents besides water • Presence of flammable constituents • Combustion properties of sample | Sensitivity to heat • Presence of volatile constituents besides water • Presence of flammable constituents • Combustion properties of sample | ||

[[File:GoodCurve.PNG|thumb|Representation of asymptotic curve, steady-state weight]] | [[File:GoodCurve.PNG|thumb|left|Representation of asymptotic curve, steady-state weight]] | ||

Physical state of sample • Surface properties, enhanced IR absorption • Even sample distribution to heat • Enhanced thermal conductivity • Ability to dissipate heat and moisture from surface | Physical state of sample • Surface properties, enhanced IR absorption • Even sample distribution to heat • Enhanced thermal conductivity • Ability to dissipate heat and moisture from surface | ||

| Line 33: | Line 33: | ||

In the example shown here (Figure 7), the sample has reached a steady state and achieved the automatic shut-off criterion. If the final value achieved is lower than the expected value, this indicates that the temperature is not high enough to release all the bound moisture; increase the temperature and repeat the measurement until an optimal temperature is achieved. Conversely, if the resulting value is too high, this could indicate that the sample has changed composition (burned); decrease the temperature and repeat the measurement. It is important to visually inspect the sample to determine if burning or charring has taken place. In other cases, samples may never reach a constant weight throughout the drying process, resulting in a drying profile similar to that illustrated in Figure 8. This type of curve is indicative of a sample undergoing thermal decomposition or continual vaporization of volatile components. Optimization in this case may require lowering the temperature profile used for drying. Timed switch-off and consistent initial sample weight also help improve repeatability | In the example shown here (Figure 7), the sample has reached a steady state and achieved the automatic shut-off criterion. If the final value achieved is lower than the expected value, this indicates that the temperature is not high enough to release all the bound moisture; increase the temperature and repeat the measurement until an optimal temperature is achieved. Conversely, if the resulting value is too high, this could indicate that the sample has changed composition (burned); decrease the temperature and repeat the measurement. It is important to visually inspect the sample to determine if burning or charring has taken place. In other cases, samples may never reach a constant weight throughout the drying process, resulting in a drying profile similar to that illustrated in Figure 8. This type of curve is indicative of a sample undergoing thermal decomposition or continual vaporization of volatile components. Optimization in this case may require lowering the temperature profile used for drying. Timed switch-off and consistent initial sample weight also help improve repeatability | ||

[[File:BadCurve.PNG|thumb|Representation of drying curve which does not reach constant weight]] | [[File:BadCurve.PNG|thumb|left|Representation of drying curve which does not reach constant weight]] | ||

In some cases, it may be necessary to determine the moisture content only using the moisture analyzer (i.e., no reference value is given or can be measured). In these cases, method development should be done as defined above, with the goal of achieving the fastest drying time and most repeatable results. Several measurements should be made to identify and validate a sound method. Please note that the result may not indicate the actual moisture content, but instead serve an analog or proxy to the moisture value (i.e., while the final value is not the full and true moisture content, deviations in the actual moisture content of a sample can be detected). | In some cases, it may be necessary to determine the moisture content only using the moisture analyzer (i.e., no reference value is given or can be measured). In these cases, method development should be done as defined above, with the goal of achieving the fastest drying time and most repeatable results. Several measurements should be made to identify and validate a sound method. Please note that the result may not indicate the actual moisture content, but instead serve an analog or proxy to the moisture value (i.e., while the final value is not the full and true moisture content, deviations in the actual moisture content of a sample can be detected). | ||

Revision as of 16:51, 29 June 2021

| OHAUS MB120 Moisture Analyzer |

|---|

| Sample Size: 0.5 g – 120 g |

| Readability Moisture Content: 1 mg/0.01% |

| Pan Size: 3.5 in (90 mm) |

| Heating Profiles: Standard, Ramp, Step, Fast |

| Temperature Range: 40 °C – 230 °C |

The moisture analyzer provides precise measurements of moisture content in liquid, paste, and solid materials.

Principle

The MILL's moisture analyzer measures moisture via the loss on drying technique. These type of moisture analyzers define moisture as the loss of mass observed when the sample is heated and is based, in theory, on the vaporization of water during the drying process; this measurement does not distinguish weight loss of water from loss of volatile components or sample decomposition. A heating element (such as a halogen bulb) dries a sample by transferring energy using both radiation and conductive heat transfer, and a precision balance that monitors the weight loss during the drying process. The loss on drying technique is universally recognized as an efficient, reliable, and cost-effective method for determining moisture content.

Designing Testing Protocol

When designing and optimizing the testing protocol, it is important to understand your material. Consider the following three factors before getting started:

Approximation of moisture content • Based on information in the literature • Calculated from starting ingredients • Estimated by comparison to related materials

Sensitivity to heat • Presence of volatile constituents besides water • Presence of flammable constituents • Combustion properties of sample

Physical state of sample • Surface properties, enhanced IR absorption • Even sample distribution to heat • Enhanced thermal conductivity • Ability to dissipate heat and moisture from surface

The most common way to develop a method for a particular substance is to obtain a reference value, then build a method to reproduce the target value with the shortest possible drying time. To obtain a reference value, use the conventional LOD procedure and an analyzer and drying oven. Alternatively, you may use a desiccator, Karl Fisher titrator, or other methods. Once you have obtained a reference value, you can begin to develop an appropriate method on a moisture analyzer. We recommend preparing a sample and drying it using a best-guess temperature, then analyzing the resulting drying curve.

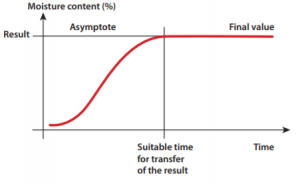

Understanding the drying curve generated during sample drying will help to define appropriate test conditions for your sample. Asymptotic drying curves are indicative of samples which reach a constant moisture value during the drying process. Optimizing the temperature profile and shut-off criterion is generally simple, resulting in repeatable data.

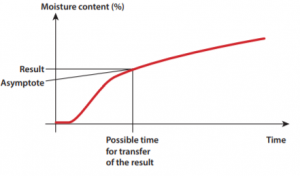

In the example shown here (Figure 7), the sample has reached a steady state and achieved the automatic shut-off criterion. If the final value achieved is lower than the expected value, this indicates that the temperature is not high enough to release all the bound moisture; increase the temperature and repeat the measurement until an optimal temperature is achieved. Conversely, if the resulting value is too high, this could indicate that the sample has changed composition (burned); decrease the temperature and repeat the measurement. It is important to visually inspect the sample to determine if burning or charring has taken place. In other cases, samples may never reach a constant weight throughout the drying process, resulting in a drying profile similar to that illustrated in Figure 8. This type of curve is indicative of a sample undergoing thermal decomposition or continual vaporization of volatile components. Optimization in this case may require lowering the temperature profile used for drying. Timed switch-off and consistent initial sample weight also help improve repeatability

In some cases, it may be necessary to determine the moisture content only using the moisture analyzer (i.e., no reference value is given or can be measured). In these cases, method development should be done as defined above, with the goal of achieving the fastest drying time and most repeatable results. Several measurements should be made to identify and validate a sound method. Please note that the result may not indicate the actual moisture content, but instead serve an analog or proxy to the moisture value (i.e., while the final value is not the full and true moisture content, deviations in the actual moisture content of a sample can be detected).

Drying Profiles

Moisture content (MC) is greatly influenced by the drying temperature used to drive off the moisture. Excessive heating may result in a high percentage MC reading due to sample decomposition or changes in chemical structure. Besides giving artificially high readings, results are very difficult to reproduce in tests when the drying profile is too harsh. Conversely, lower heating levels may preserve sample integrity but prolong the drying process, making the test unrealistic for process use. The MB Series of moisture analyzers offers a series of drying programs that allows users to customize the sample drying profile. By customizing the drying program, moisture measurements can be optimized to enhance drying conditions and shorten runtime while minimizing sample decomposition or change in chemical structure, ultimately improving testing accuracy and reproducibility. The four basic temperature profiles—standard, fast, step, and ramp—can be customized by specifying a target temperature(s).

Shut-Off Criteria

A shut-off criterion defines when the moisture analyzer stops heating and considers a measurement complete. This can be done either manually or via several built-in options to ensure accurate, reproducible results. When and how the instrument terminates a heating profile can be programmed according to runtime or according to steady-state weight conditions. The available switch-off criteria are:

1. Manual – The user defines the end of the run and shuts off the instrument manually.

2.Timed – Instrument shuts off automatically at a preset time during analysis (e.g., 10 minutes).

3.Auto – The instrument automatically shuts off based on weight loss per unit time. For the built-in automatic shutoff criteria, the end of a measurement is reached when the overall change in weight observed is less than 1 milligram per period of time. The available preprogrammed choices are:

A30 = < 1 mg. weight loss in 30 seconds (quick-drying samples/fast measurements)

A60 = < 1 mg. weight loss in 60 seconds (most sample types)

A90 = < 1 mg. weight loss in 90 seconds (slow-drying samples)

4.AFREE – Auto-free switch-off; allows the user to define shut-off criteria according to weight loss per unit time

Applications

Moisture content analysis is a critical component of material quality and essentially a function of quality control in most production and laboratory facilities. Excessive or deficient moisture content of a substance can adversely impact the physical properties of a material. Weight, thermal expansion, amalgamation, electrical conductivity, and microbial activity are some examples of the properties that can be altered by even a minute presence, or, conversely, an abundance of moisture. In many industries it is important—if not critical—to measure the water content of substances in order to assess quality, adjust manufacturing processes, and ensure that products meet regulations and guidelines.