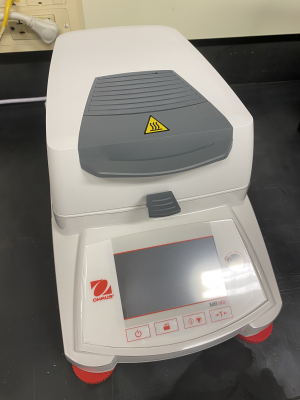

Moisture Analyzer

| OHAUS MB120 Moisture Analyzer |

|---|

| Sample Size 0.5 g – 120 g |

| Readability Moisture Content 1 mg/0.01% |

| Pan Size 3.5 in (90 mm) |

| Heating Profiles Standard; Ramp; Step; Fast |

| Temperature Range 40 °C – 230 °C |

The moisture analyzer provides precise measurements of moisture content in liquid, paste, and solid materials.

Principle

The MILL's moisture analyzer measures moisture via the loss on drying technique. These type of moisture analyzers define moisture as the loss of mass observed when the sample is heated and is based, in theory, on the vaporization of water during the drying process; this measurement does not distinguish weight loss of water from loss of volatile components or sample decomposition. A heating element (such as a halogen bulb) dries a sample by transferring energy using both radiation and conductive heat transfer, and a precision balance that monitors the weight loss during the drying process. The loss on drying technique is universally recognized as an efficient, reliable, and cost-effective method for determining moisture content.

Applications

Water is essential to life; it plays a critical role in the physical and chemical functions of our bodies, the food we eat, and the materials that surround us. Moisture content can be thought of as the amount of water in a material or substance. Moisture content analysis is a critical component of material quality and essentially a function of quality control in most production and laboratory facilities. Excessive or deficient moisture content of a substance can adversely impact the physical properties of a material. Weight, thermal expansion, amalgamation, electrical conductivity, and microbial activity are some examples of the properties that can be altered by even a minute presence, or, conversely, an abundance of moisture. In many industries it is important—if not critical—to measure the water content of substances in order to assess quality, adjust manufacturing processes, and ensure that products meet regulations and guidelines.